What is the

difference between synthetic and conventional oil?

Oil, whether synthetic or petroleum-based, consists of molecular chains of

hydrogen and carbon atoms, referred to as hydrocarbons. Petroleum crude oil is a

thick, highly flammable dark-brown or greenish liquid with high energy

densities. Many contaminating elements exist in this complex mixture of

hydrocarbons, including sulfur, nitrogen, oxygen and metal components such as

nickel or vanadium. Petroleum crude oil is the raw material used for a wide

variety of petrochemicals, including solvents, fertilizers, plastics and

lubricants.

The oil refining process separates the various types of

molecules in the oil by weight, resulting in a concentrated batch suitable for

today’s uses such as gasoline, LPG, kerosene or base oils for lubricants. The

chemical composition of conventional motor oil can vary substantially and

depends on the raw crude oil refining process.

While petroleum base oils

are refined, synthetic base oils are manufactured and can achieve a higher

performance level. Synthetic oil is chemically engineered for a certain

molecular composition with a tailored and uniform structure. Such fine-tuned

control over the final molecular composition of synthetic oils is the key to the

superior performance properties of these fluids. Designing molecular structures

in a planned and orderly fashion results in molecules, and end-products, that

are far more stable than their refined petroleum counterparts.

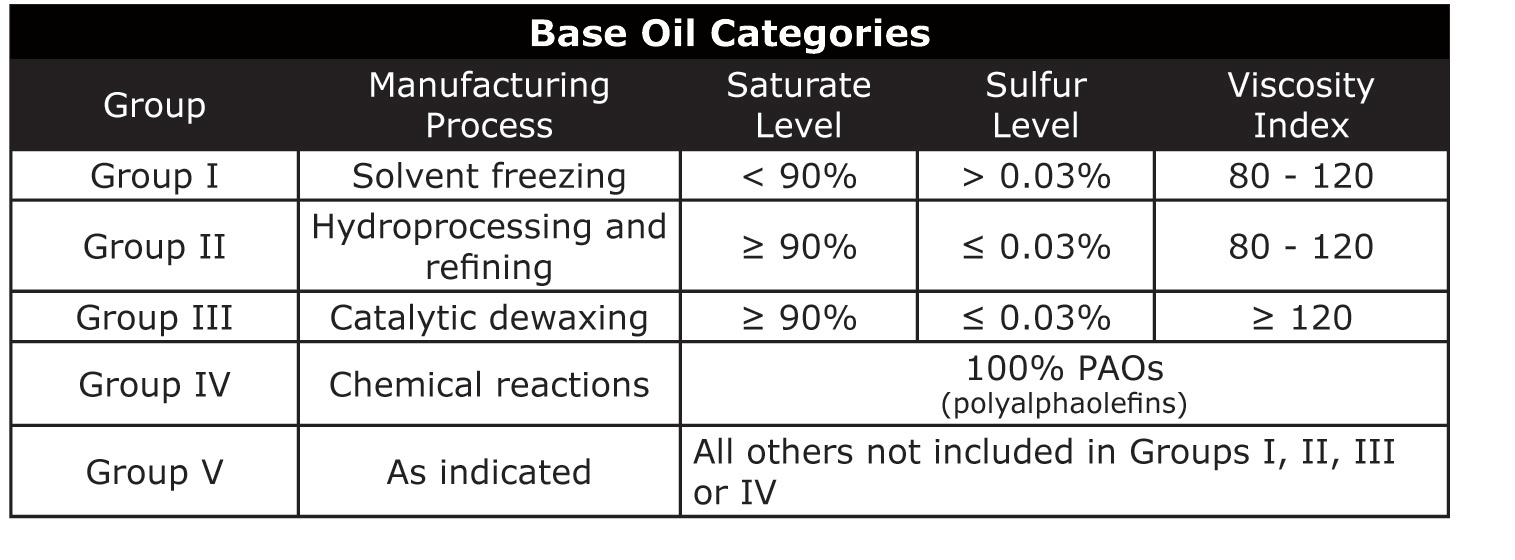

Base Oil Groups

The entire range of base oils, including conventional petroleum products, are

divided into five groups based on the level of saturates (saturated molecules),

sulfur and viscosity index. In general, the chemical composition and performance

properties of the base oil categories improve with advancing group number. For

instance, Group I has a lower concentration of saturates than Group II, while

Group II has a lower concentration of saturates than Group III base oils. Today,

Group III, Group IV and Group V base oils are considered synthetic.

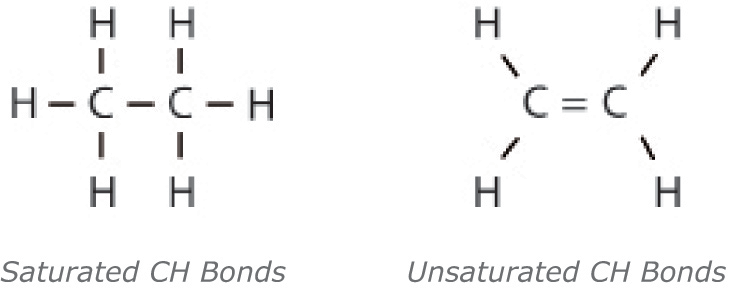

Saturated molecules contain a higher percentage of

carbon-hydrogen (CH) bonds, which limits the available sites to which other,

harmful molecules can attach. When other molecules, such as oxygen, attach to

oil molecules, they break down the molecular composition of the oil and weaken

its performance. Saturated molecules are beneficial in lubricating fluids

because they remain stable longer, resulting in a more durable lubricant.

Unsaturated molecules have fewer single carbon-hydrogen bonds and are therefore

less stable.

Sulfur is a naturally occurring, inorganic element that

readily reacts with oxygen molecules and is detrimental to oil performance.

Synthetic base oils have less sulfur than conventional base oils.

Viscosity

index refers to the temperature-viscosity relationship of lubricating fluids.

Oils with a high viscosity index (VI) are less affected by temperature; those

with low VI are affected more. Oils with a VI less than 120 (Groups I & II)

are more susceptible to viscosity variance because of temperature. The viscosity

index of synthetic base oils is higher than that of conventional petroleum base

oils.

Viscosity index refers to the temperature-viscosity relationship of

lubricating fluids. Oils with a high viscosity index (VI) are less affected by

temperature; those with low VI are affected more. Oils with a VI less than 120

(Groups I & II) are more susceptible to viscosity variance because of

temperature. The viscosity index of synthetic base oils is higher than that of

conventional petroleum base oils.

Pure, Uniform Molecules Form Strong, Stable Lubricants

Petroleum oils have molecular structures that are randomly organized and,

consequently, have limited performance abilities. Their varied and inconsistent

molecular structure results in less film strength and lubricity. Their

paraffinic wax content also makes them more susceptible to viscosity variance

and cold-temperature flow problems.

On the other hand, synthetic base oil

molecules are chemically controlled, which provides increased film strength and

lubricity over petroleum oils.

The performance qualities of base oils

have a marked impact on the performance qualities of the finished product.

Synthetic base oils provide key features and customer benefits including better

wear protection, more horsepower, increased engine cleanliness, improved fuel

economy, easier cold starts and longer oil life.

What roles do additives play in motor oil

performance?

Most lubricating oils have other chemicals added to improve the overall

performance of the fluid. Chemical additives are used to enhance the beneficial

properties of the base oil or to make up for oil deficiencies. For passenger car

motor oils, base oil makes up 70 percent to 80 percent of the final product; the

other 20 percent to 30 percent is comprised of additive

chemistry.

Additives help lubricants stand up to extreme operating

environments. Even the best base oil would not be able to protect as well

against the effects of heat, shearing forces, chemical and water dilution,

corrosion and wear particles. In short, additives make good base oils even

better. They give good base oils the performance benefits consumers have come to

expect, such as multi-grade performance, extended drain intervals and

extreme-pressure performance.

Anti-wear Agents chemically react to

form a film barrier that prevents metal-to-metal contact and

wear.

Antioxidants reduce the tendency for oil to react with

oxygen and reduce sludge buildup.

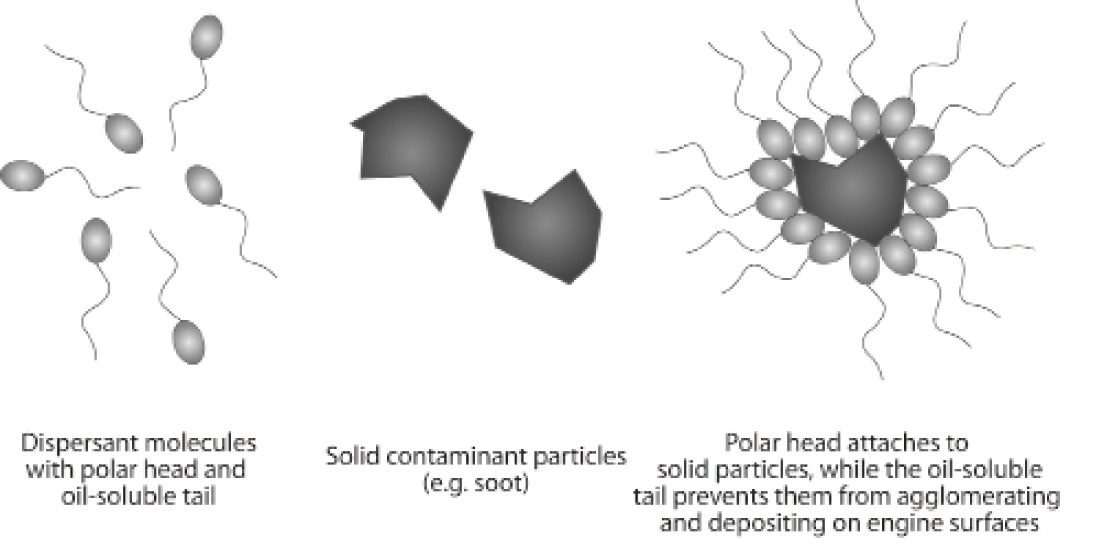

Dispersants help to suspend and

disperse contaminants in the oil to keep engine surfaces free of sludge and

deposits. They fight the build-up of corrosive acids and are most efficient at

controlling low-temperature deposits.

Detergents help to suspend and disperse contaminants in

the oil to keep engine surfaces free of sludge and deposits. They are most

efficient at controlling high-temperature deposits.

Extreme-Pressure

Additives coat metal surfaces to prevent close-contact components from

seizing under extreme pressure. They are activated by high temperatures and high

loads to react with the metal’s surface to form a sacrificial wear layer on

components.

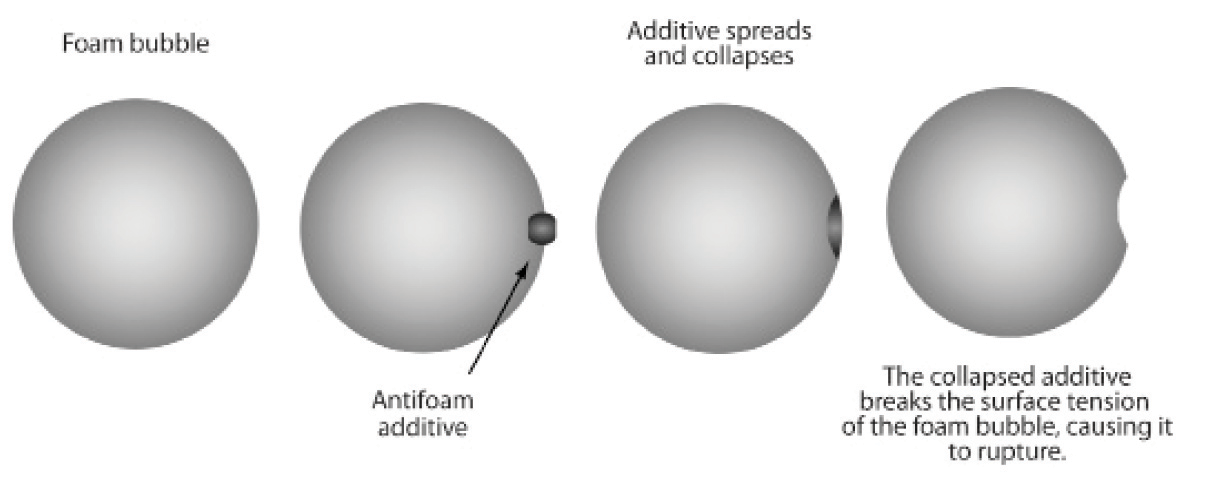

Foam Inhibitors reduce the surface tension of air

bubbles and causes them to collapse.

Friction Modifiers can be used to give oil more ‘slippery’

characteristics. In engine oils, friction modifiers are used to increase the

oil’s lubricity for the purpose of reducing friction and improving fuel

economy.

Pour Point Depressants give high-viscosity oils good

low-temperature properties. Pour point depressant polymers inhibit the formation

of crystals to minimize low-temperature viscosity increase.

Rust &

Corrosion Inhibitors form a protective barrier over component surfaces to

seal out water and contaminants. While most rust and corrosion inhibitors work

by forming a physical barrier, some rust inhibitors function by neutralizing

acids.

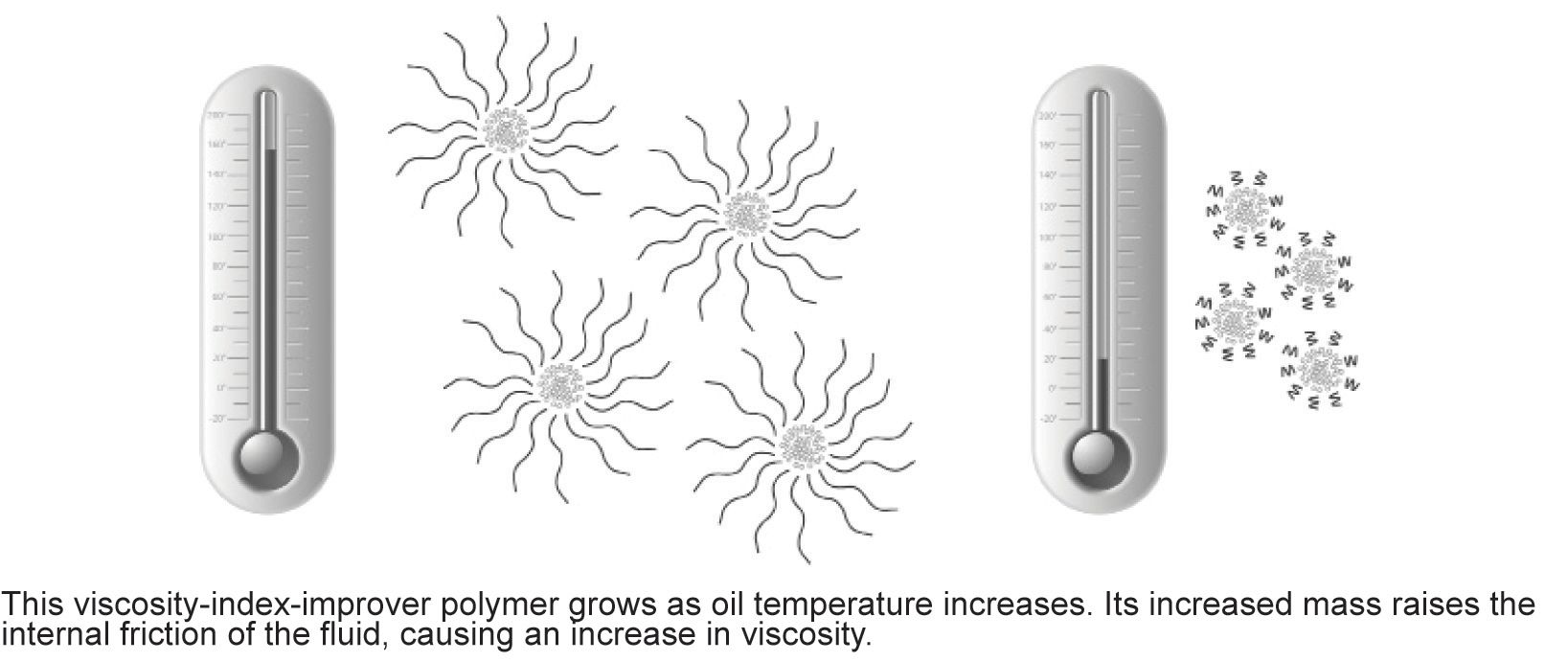

Viscosity Index Improvers are long-chain polymers that help

control the viscosity of multi-grade engine oils. They expand and contract as

temperatures vary. High temperatures cause VI improvers to expand and reduce oil

thinning; low temperatures cause the VI improvers to contract and have little

impact on oil viscosity.

|